How often are prescription safety glasses inspected at your facility? When do you replace safety lenses and frames?

Our safety lens replacement guidelines are simply defined: Lenses that are cracked, pitted, chipped and heavily scratched provide no protection to the worker and must be replaced as soon as possible.

Safety frames should be replaced as soon as possible after the frame is discontinued for replacement side shields will not be available. And you don't want this to happen with universal replacements

Just like your employees' safety footwear; safety frames should be replaced when they are dented, damaged, or their ability to be worn safely has been compromised. In my experience safety frames which have been worn over 4 years should be regularly inspected. Make sure the screws holding the lenses stay tight so the lenses won't fall out or be ejected into the wearer's eye. And solders to the frame's stress points must not have weakened.

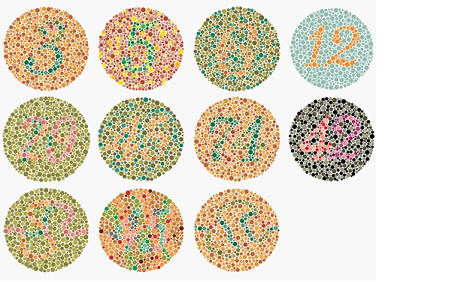

: Is your signage readable by everyone on your staff?

Overall, between 7 - 10% of the male population is color blind. When you break down the numbers; 8% of male Caucasians, 5% of Asian males, and 4% of African Amercians are deficient in red green perception. Below are the signage guidelines. Be sure to identify any member of your staff who is color deficient and screen new hires to make sure they can see the warning signage to keep them from harm

Red is for danger. Red danger signs and tags with contrasting black or white lettering are used only in areas where an immediate, serious hazard—one that can cause death or serious injury—exists. Flammable liquids are typically marked in red. Red markings are also used for some safety equipment, such as emergency stop bars, buttons, and switches.

Yellow is for caution. Yellow and black caution signs and tags warn about potential hazards or unsafe practices that could cause minor injuries. Wet floors, radiation, and “Do Not Enter” signs are often found in the form of yellow caution signs.

· Green is for safety. Safety instruction signs have a white background, a green panel, and black and white letters or markings. These signs provide general safety information. For example, they are used to mark the location of emergency exits, first-aid kits, and safety equipment.

Specific application prescriptions

Wouldn’t it be great if one pair of safety glasses could do it all? Unfortunately not every visual task falls in the “normal” corrective lens ranges: Near work 18- 22 inches, arms length activities 2 - 3 feet, and distance viewing 3 feet to infinity. For example: the mechanic or electrician who is working above his head; standing on a ladder, his head tilted backwards (30 degrees or more) trying to see his work through his flat top bifocals or trifocals? I have an optical solution, the double D bifocal, to improve his visual accuracy and reduce the likelihood of a fall

Maybe you’ve observed computer users; their chins raised up 10 - 15 degrees, trying to view their work on the computer monitor through their progressive bifocals? The appropriate computer progressive will eliminate the likelihood of an ergonomic injury while reducing visual fatigue and improving their visual productivity

Perhaps you’ve noticed employees constantly moving their heads up & down, left to right; in order to find the clearest focus point through their bifocals. The correct bifocals with wider fields & less distortion will provide uninterrupted visual performance at both near, intermediate and far. The correct prescription can improve productivity by as much as 38%.

Are you receiving employee complaints concerning glare, reflections, and blurred vision when non prescription eyewear is used over their own glasses? I have optical solutions to minimize the risk of an eye injury while guaranteeing clear, sharp vision with comfortably fitting frames.

As the workforce ages you will encounter more issues which are vision related. Specifically you'll see an increase in the number of employees using bifocals and computer/reading related eyewear. As a person ages; the bifocal power increases which affects the distance that an object may be seen clearly. Translated: employees will be getting closer to their work whether it's assembly, machine operation, welding, computers, and .......

Just last week I helped design safety glasses for an employee who worked at a near point of just 5 inches and his arms length task was at 22inches. For this very reason I strongly recommend your employee utilize my vision discovery instrument WIDE. This should guarantee the employee’s doctor arrives at the prescription best for their work activity. Safety lenses are available to address every possible visual task you can imagine. My responsibility is designing the correct visual aid. If you have any questions regarding specific application prescriptions; please call my office at 708-686-5266

March is Workplace Eye safety month. Recently respondents were asked to rank the most important PPE category for on-the-job safety. Protective eyewear came in first and was also deemed the most challenging PPE category in terms of compliance, How can you ensure compliance?

· When asked what would most improve compliance with eye protection protocols, the top choice was more comfortable eyewear—with features like flexible, comfortable nose pieces (56%), followed by fog-free lenses (22%).

Comfort solution is as easy as replacing the over the glasses one size fits all PPE with plano, prescription safety frames and lenses fit to the precise size requirements of the individual employee. For employees already wearing safety glasses encourage them to have their safety glasses readjusted when Vision Xperts is on site at your facility. No frame will stay in proper adjustment for a year, not even mine!

· 88% of respondents saying they or someone they worked with had been unable to see or complete a task properly because of fogged lenses. Also, 40% of respondents reported this had happened on numerous occasions.

Lighting in the average workplace ranges from 50 to 500 lux (measurement of illumination equal to the intensity of one candle). The proper use of lighting has shown to reduce the loss of alertness, production errors, and accidents. For nightshift workers and those employees who work on rotating shifts

this is especially true. I recommend adding supplemental task lighting, rather than more overhead lighting, to workstations to adequately illuminate tasks which is more critical for older workers.When was the last time the wattage of lights over workstations was checked, burned-out bulbs replaced, and lighting fixtures cleaned and dusted routinely?

· Incandescent. This type of lighting was invented by Thomas Edison and has been used for over 100 years. Modern technology has reduced glare through the development of soft white, reflector, and other types of bulbs.

· Halogen. This type of bulb is often used in task lighting and track lighting because it saves energy.

· Fluorescent. New energy-saving fluorescent bulbs can be used as direct replacements for incandescent bulbs. They give more realistic color quality and can save as much as 75 percent in energy cost.

· Full-spectrum. These new bulbs simulate the full-spectrum light of natural sunshine. Not only do they reduce eyestrain, but they have the added dimension of improving mood, especially during the shorter days of winter or for night workers. Studies also show that worksites with full-spectrum lighting have half the absenteeism for illness than those that do not.

· Sunlight. It is obvious, but the effective use of natural sunlight to reduce the use of artificial lighting and eliminate over lighted or under lighted areas should be a priority.

Protecting workers' eyes whose job is outside during the winter falls into two categories: UV radiation and ocular dryness. We normally associate the need for sunglasses during the summer. But did you know that snow reflects 85% of the sun's radiation? While sand and concrete reflect approximately 25%. And if you think the higher amount of cloudier days in the winter will protect you; think again. A thin cloud cover only reduces UV radiation between 20-40%.

If you’re not wearing the right eye protection, especially people with fair or light colored eyes who are at higher risk, you can actually "sun burn" your eyes. The outer layer of the eyeball known as the cornea; is similar to the outer layer of your skin. When it is burned by the sun’s rays, the cornea becomes inflamed ( called keratitis) which can be quite painful and can cause temporary blindness. Like sunburns to the skin; burning your cornea causes cumulative damage. Eye issues like cataracts, skin cancer of the eyelids and melanoma in the retina are all possible risks from sun-damaged eyes. I cannot stress the importance of protecting outside workers against both UVA and UVB rays. Remember reflected UV radiation is just as damaging as direct UV radiation.

In January the average daytime temperatures in Chicago are between 18 & 31 degrees. If you add a 5 mile an hour wind the temperature on your unprotected eyes is between 13 and 19 degrees, with frostbite occurring in less than 30 minutes (NOAA's latest wind-chill chart). It takes less than 1 hour outside for the eye's tear film to be disrupted and possible ocular surface damage

Solutions: We have a number of wrap style safety frames in metal, plastic, and nylon materials, not to mention various lens colors and coatings, to help protect outside workers. By adding Optifog you increase these workers safety factor. I recommend that your facility incorporate natural tears such as Blink for employees to use after they've finished their outside activities. Dry eye for outside workers while not a "reportable" condition can have long term damaging effects. I provide this 25 unit lubricant @ $8.95. Please call my office to place your order.

90% of eye injuries are preventable yet 60% of those injured did not wear their eye protection. The result is a visit to the emergency room.... Injury to the cornea was suffered the most followed by Laceration of skin of eyelid and around eye area, bruise of eye, and Bruise of orbital tissues

Practice Safe Specs: The winter forecast is here! During November we see the greatest one month drop in average daily temperatures. As outdoor temperatures drop Lens fogging increasingly becomes a safety issue for not only outside workers; but employees in areas where they're frequently exiting and entering such as drivers, forklift operators, dock personnel.

Fogging has an solution. Optifog is a product I have tested and use to address fogging of optical lenses. I invite you to visit the following YouTube site for a presentation. http://www.youtube.com/watch?v=Ww8GO673P8Q. For pricing information please contact our office 708-686-5266

Don't let this happen to your employees' safety glasses

The damage on the bottom of this safety lens is due to being left inside an auto when the outside temperature is 90 degrees. The lens actually melts

eye injuries still occur at an alarming rate:2,000 daily and over 100 each day result in days away from work. The black and white details: 5% of eye injuries result in loss work time and 33% require hospital treatment. 81% of eye injuries are suffered by men. Specifically: if you are a male between the ages of 25- 44 and it's a Monday after lunch and you don't have the proper eye protection you have an 80% chance of suffering an eye injury. 39% of eye injuries occur in various types of offices, laboratories, and hospitals. 61% occur in manufacturing and trade occupations. Specifically operators, fabricators ,laborers, precision production, crafts, repair occupations, and assemblers. The top three causes of eye injuries: foreign body in the eye, abrasion to the eye, and chemical burns of the eye. 90% of eye injuries are preventable.

while I am adjusting and fitting the safety glasses (which is right in front of them) I remind your employees to avoid home repairs to their eyeglasses. I'll point out using boiling water, microwaves, and stoves to warm the plastic frame parts will only damage the frame and lenses. And I don't want your employees to get hurt. These are all bad ideas for they'll void the manufacturer warranty. Well it's amazing what you won't find on the Internet. So I am going to add not to use hair dryers either.

Liquid based makeup should be replaced every 6 months to avoid eye irritation and infections. Avoid storing makeup in a room/auto which gets hot as bacteria may grow in the makeup. Makeup should be removed before going to bed especially if you wear contact lenses. If an eye infection occurs; all cream/liquid base makeup should be discarded. With lip and eye pencils it's best to shave off the tops before using. Be sure to use liquid soap and warm water on your frames at least once a week to remove makeup that may collect on your eyeglass frame and lenses.

As the workforce ages many employees find themselves struggling to see clearly their computers and reading materials. A majority of the time eye doctors will recommend progressive (no line) bifocals. Unfortunately the eye doctor or staff does not really explain options to address a patient's visual struggles or how a progressive bifocal works. Having worked with progressive bifocals since their introduction over 25 years ago; I'm always happy to review with your employees how they can apply the progressive bifocal to their work.

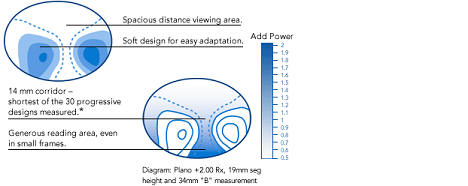

The diagram below reveals the basic structure of a progressive bifocal. The top part of the eyeglass lens is for viewing the distance (beyond the length of your outstretched arm). The area in the lens directly below the top and in between the dotted lines is for viewing at approximately 20 - 24inches. The very bottom of the lens in between the dotted lines is for the reading distance. The areas outside of the dotted lines along the sides of the lens are unusable (usually blurred).

Selecting the appropriate style of progressive bifocal can make all the difference between success and failure. Designing the progressive bifocal for a patient is based upon factors such as the prescription strength, what they are viewing, if the person stands or sits, their height, and how they "sit". Some progressive bifocals have wider zones between the dotted lines. A limited number of progressive bifocals are made just for viewing the computer. There are progressive bifocals made to fit into just small frames.

In my opinion progressive bifocals are a phenomenal optical tool. The ability to see clearly at a distance, medium range, and up close in one pair of glasses is truly remarkable. But progressive bifocals have two drawbacks. Progressive bifocals are very "distance dependent" . And as the power of the bifocal increases; the zone for viewing the computer and reading "shrink". (People who are nearsighted really dislike this feature) For these prescriptions there are now "designer" progressives to accommodate the patient's higher power requirements. Frankly some progressive bifocals have been around since their inception 20+ years ago and their designs; while less expensive are not up to today's technical viewing demands.

So I recommend when your employees visit their eye doctor have them bring their visual profile. This visual profile will provide the eye doctor a comprehensive picture of what the person does with their eyes. And with this information their eye doctor can select one of the 300 progressive bifocals which will work best. In my wellness programs Combating Visual Fatigue and Avoiding Computer Vision Syndrome

I discuss how to ensure their best visual accuracy and performance with their prescription eyewear for I know the incorrect prescription reduces a persons productivity by 20%

The Bureau of Labor statistics reports only 40 percent of workers with eye injuries wore eye protection. The most common " reasons" I hear from employees as to why they don't use their safety glasses: the prescription is outdated, the lenses are scratched, the frame is not comfortable/broken, and I left the glasses at home. I recommend that you check eyewear for damage that employees have been using for over 2 years. Encourage your employees to visit with me when I'm on site so I may adjust and repair their safety eyewear . I can keep the eyewear comfortable and protecting employee's eyesight at maximum efficiency. If employees need a 2nd pair of eyewear for at home; I offer the same first quality frame & lenses to your employees at the best prices that you pay for their safety eyewear.

I always have in my traveling office over 60 different safety side shield styles and sizes to address any replacement. A week doesn't go by without an employee requesting side shields - for their dress eyewear. Rarely would these safety side shields properly fit a dress frame. And it would be dangerous for an employee to believe they had proper eye protection with side shields on their dress eyewear. So for these requests I recommend instead fabricating the proper safety eyewear.

Do you know what steps to follow if one of your employees has pink eye or blepharitis? For pink eye it would be best if the employee remains at home until the condition clears since they will be very sensitive to light, their vision will be blurred, and it's highly contagious. Blepharitis usually impacts the eyelids and eyelashes of the individual and is not considered contagious. For both conditions; using soap and warm water to cleanse the safety eyewear is recommended. For any safety eyewear, equipment or tools which are shared; use individually packaged alcohol wipes to disinfect the affected materials surfaces. Be sure to remind employees to wash their hands.

Backup plan... do you have a back up? It’s not often I have an employee whose eyewear has broken. In 2010 only five employee frames required replacement ( 2 were covered by warranty). And you know I can usually replace prescription safety lenses without taking the employee’s frame. But some frame styles which have the latest ANSI design for lens retention require new prescription lenses cannot be made without the actual frame. So what’s the plan if your current frame or lenses break? I recommend that when you get new glasses keep your present eyewear as your backup. And I’d keep it handy for the backup is no good if it’s in the drawer at home. If your current safety frame does get damaged I will first try to use parts from my inventory, at no charge to you, since the frame companies no longer sell parts. For those of you wearing contact lenses be sure to have your carrying case, and back up glasses available if your contact lenses need to be removed.

Adjustments ....when I fit or readjust your safety eyeglasses I am checking three vital aspects which affect how you see through your eyeglasses. As I check from each side of your face, straight ahead, and from above your eyebrows I am checking Pantoscopic Tilt, wrap angle, and vertex distance alignment. These aspects make all the difference between clearer, wider more comfortable near vision, wider field of vision, and overall visual accuracy. Ask your eye doctor's staff to adjust your dress eyewear in the same manner.... or bring them along with your safety glasses and I'll take care of both.

Nose Pads....The 2nd most asked reason for frame adjustment has to do with the nose pads. The nose pads provide 2 significant functions: main support of the frame's weight and they maintain the lens optical center in position in front of your pupils. When the eyeglass frame is out of adjustment, all of the frame's weight transfers onto the nose pads. When the eyeglass frame is loose your ability to have clear sharp focus is reduced (especially bifocal wearers) because the lens optical center is too low. This is why we push our glasses back up. Nose pads are available in a range of sizes from as small as a collar button to over 20mm lengths. If your nose pads are not comfortable or they've worn out (cracked, discolored, broken) remember Vision Xperts does not charge for nose pad replacements.

Winter driving.... As winter arrives there are many recommendations to safely traverse the roadways. With the switch back to standard time means many employees will be driving to and from work with the sun low in the horizon. For example here in Chicago in June the sun is as high as 70 degrees. In December the sun doesn't get any higher than 30 degrees. Glare is an issue from the sun and oncoming car lights. To minimize the effects of glare while driving: don't use high gloss cleaners on the dashboard for it will reflect the sun's glare upward into your eyes. Wear sunglasses with a level three tint (Transitions don't darken inside the car) and incorporate an antireflective coating for your prescription lenses to improve clarity. Replace your prescription lenses if they are heavily scratched, keep your GPS/phone devices positioned so you can check them through eye movement (like your outside mirrors) instead of moving your head. And of course keep the windshield clean inside and outside (how's your windshield fluid level?),

Cracking... since the Z87 update and the introduction of high impact polycarbonate lenses; the issue of cracked lenses entered the safety arena. When I next visit your office I'll show you a lens where a crack has traversed almost the entire length of the lens. I recommend that frame and lenses be regularly inspected for any damage which would compromise their safety effectiveness. If an employee notices a crack; please contact me immediately. The lenses have a one year warranty against cracking and will be replaced at no charge. Safety glasses also have a one year warranty which covers any damage unless caused by a pet (usually a dog chewing) or loss. Cracking is rare; I've only replaced two all year under warranty; but lenses should not be worn with this damage.

Can glasses make me itch? Did you ever notice when you remove your glasses that the finish has come off from the temples? Have you worn inexpensive jewelry only to find it left a discoloration on your skin when removed? These scenarios would tell me that you are probably alloy sensitive. Those individuals who continue to wear ophthalmic frames their body is "allergic" to will notice a redness along the skin wherever the frame makes contact with their facial features. And it can get pretty sore and uncomfortable. For these cases I would recommend using either a plastic, stainless steel, or a titanium frame. These frame materials will eliminate any further reaction between the metal and the skin. And it is important to note that you can wear glasses for many years and this alloy sensitivity will seem to just appear.

Paper clips, twisted wire, staples, super glue and toothpicks..... I've seen these and more to replace a lost screw. While I remove these sharp objects the question arises "Why does that screw fall out?" The taking off and putting on (especially using one hand) forces the screws to loosen. Before the screw actually falls out; the loosened screw holding the lens into the frame will cause the lens to wiggle while cleaning. The loosened screw holding the temple will cause that side to wobble before the screw "disappears". So before the lens falls out and is damaged, the temple hinge breaks or the employee is injured by the sharp object replacing the screw; please remind your staff to see me for adjustments when I visit your office. And let's work together to eliminate the Paper clips, twisted wire, staples, super glue and toothpicks.

June - August.... during my on site visits in these months ; two issues are in the forefront. "My safety glasses keep slipping down" and "the lenses keep fogging up". As I mentioned in last month's issue; sweat can cause more than one difficulty and I urge your employees to see me when I next visit your facility so I may properly adjust and tighten their prescription safety glasses. If fogging is an issue; the best remedy is to use an eyeglass cleaner such as I provide or is contained in the eyeglass cleaning stations (be sure to keep 'em full). I personally find that cleaning the frame and lenses with dishwashing soap at the end of each day does a very effective job of removing all of the dirt and oils which contribute to fogging. When ordering new safety eyewear be sure to ask for the anti fogging coating option.

Sunglass 101 For optimum protection consider polycarbonate lenses for they provide the highest level of eye protection from impacts and most ultraviolet rays. Sunglass lenses should be labeled as to their level of ultraviolet protection. Don't just assume a dark looking lens has the most protection level. Brown, green, and gray are the best lens colors for summertime daylight usage. Mirror coatings enhance the protection levels of these colors. Avoid blue tinted lenses as they allow the yellow spectrum of light to adversely affect the inside of your eye. Polarized lenses block the blinding glare from light reflected off water, snow, and metal surfaces but will make LCD screens appear black. A wraparound style frame such as the Snake Wear style 03 will minimize peripheral light and glare.

Got Nail polish? The standard "go to" when a screw keeps loosening is not the "cure all". After washing the glasses a couple of times the nail polish is gone. Today screws usually loosen because they are stripped, they are made of softer metals which don't grip as tightly, or the frame misalignment is stressing the screw. So if a loose screw is driving you crazy be sure to see me when I visit your office. Besides properly adjusting the frame; I will replace the screw and retap the mounting. No more loose screws; guaranteed!

Doffing and Donning.....if your office is experiencing a multitude of side shield breakages; it might be time for an employee training update. Doffing and donning aren't usually applied to prescription eyewear but removing safety glasses with one hand increases the likelihood of side shield damage. Using one hand pulls the frame away from the face placing higher stress on both the rear & front points of the side shield especially if they're permanently attached. The one hand technique also loosens the frame more quickly and puts the frame at a higher risk of damage. Two hand usage for putting the safety glasses on and removing them should reduce breakages.

Help I'm melting.... we all enjoy the coming of spring and the warmer temperatures of summer.. As the outside temperature rises so does the temperature inside a closed auto or truck cab. In fact temperatures can enter into a hundred degree plus range. Unfortunately both the lenses and the plastic parts of your eyewear do not react favorably to these high temperatures. Be sure not to store your eyewear under the visor, on the dashboard, or even on the seat. My recommendation is to take the eyewear with you for the ophthalmic lenses can warp and the plastic parts become permanently disfigured.

The Numbers mean what? ...Often employees will ask me how they can “read” their prescription and what the different classifications mean to better understand how their eyes work. The eyeglass prescription usually will have the following powers: sphere, cylinder, axis, and add. The sphere represents the power for your distance ( or reading if you don’t need glasses for driving). If you see a negative symbol (-) you are nearsighted: you can’t see at a distance without your glasses. If the symbol is a plus sign (+); you are farsighted. You can walk and talk without glasses but reading is more of a challenge once you pass 40 years of age. The numbers in the cylinder and axis columns reveal if you have astigmatism. The add power is for how much strength is required for reading with a bifocal. If you see a number in the prism column; this is a lens design to help the eye’s muscles function with more efficiency. If you or your staff have any questions regarding their eyeglass prescription; I’m always happy to explain a prescription

Vision Xperts

613 S. 2nd St.

St. Charles, IL 60174

phone: 708-686-5266

You can reach our office via email at duane@wecare4eyes.com