5 Steps for healthier and safer contact lens wear:

Rest your eyes at least one day each week from contact lens wear

Don't switch contact lens solution brands; wait till your next fresh lens

Don't try to save money by over extending the number of days you wear a disposable contact

Carry contact lens lubricant, case, and glasses; if the contact lens doesn't feel better after moistening > take it out

Do not nap or sleep with your contact lenses

5 Most common mistakes contact lens wearers should avoid:

Forgot to wash their hands with soap (contains no fragrance or lotions) and water whenever handling contact lenses

Each and every night didn't rinse out contact lens storage case with warm water/disinfecting solution {replace case monthly)

Moisten contact lenses before removal from the eye

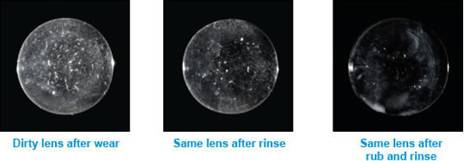

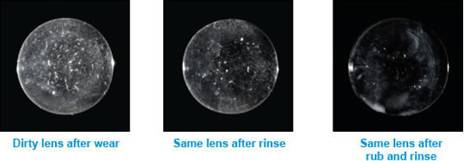

Skipped cleaning the contact lenses at night {recommend cleaning with a separate contact lens cleaner in a X pattern both sides)

Disinfecting solution requires nightly replacement you should not reuse or add to solution already used in case

11% of the US population wears contact lenses. Today prescription soft contact lenses are prescribed more and more in a "disposable" format. This could mean one day, two week, one month, or three months of usage. These types of contact lenses are more often than not in a material that is designed to stay moister while worn on the eye. Yet these type of contacts seem to collect more deposits. And deposits on the contact lenses rob that contact used more than one day of its comfort. For this reason I recommend in my wellness program (Visual Health: bottom line winner) to contact lens wearers they use one of the contact lens cleaners listed below. Having participated in numerous contact lens material and solution studies; it is my opinion if the contact lens is cleaner, the contact lens is more comfortable throughout it's prescribed usage. And there is less irritation and complications that can be traced back to lens deposits.

If the contact lens is cleaner; your visual accuracy is greatly improved. And you're not going to the eye doctor with problems related to a soiled contact lens.

* Before using any of the cleaners above be sure to check with your eye doctor that it's compatible with your current rinse/storage contact lens solution.

Brands of one day disposable contacts now available:

CONTACT LENS WEARERS LUBRICATION GUIDE

IF in the a.m. the eye has "red veins" and / or debris in corner of eyes, lubricate with natural tear and wait a half hour before inserting contacts. At end of day - If after contacts are removed your eyes feel dry ,red and are itchy - lubricate again. During the day while contacts are worn, if you feel like an eyelash is touching this is the first stage of dryness. Use a contact lens lubricant such as Blink for contact lenses, Refresh for contacts, Optifree contact lens drop or Clerz 2. One drop in the eye is sufficient, in just a few blinks the refreshment should occur and last for a number of hours. The second stage of contact lens dryness will be a blink, momentarily the vision is fuzzy and with the next blink vision is restored. Lubricate again. . If after lubrication you experience any halos or rainbows around light sources; your eye is exhausted and the contacts should be removed with no additional wear that day

Contact lenses worn in an industrial environment

Approximately(1); 34 million American adults wore contact lenses. Whether it is known to safety personnel or not; employees are wearing contacts in a variety of industrial environments. As an optician who specialized in contact lenses I wish to share my insights with the safety community. Specifically the protocols I believe are necessary to protect the employee who wears contact lenses - first responders who must attend to an injured employee wearing contact lenses - and the business entity.

Contact lens materials and designs have advanced tremendously over the past 30 years. Today’s contact lenses now remain cleaner, more comfortable while worn on the eye. These advancements have lead to a healthier use of contacts for the wearer. Disposable soft contact lenses can be replaced daily, weekly, monthly, or quarterly. Prescription options now make it possible for bifocal contacts, a wider field of vision and enhancement of the eye’s muscle coordination. Contact lenses can even change brown eyes to blue. But it is important to remember contact lenses are classified by the Food & Drug Administration as a medical device requiring a doctor’s prescription(2).

EMPLOYEE If the employer permits contact lens use then….The employee’s first step must be to communicate to the eye doctor their intention for wearing contact lenses in an industrial environment. There are a number of critical variables that may affect the doctor’s final choice of a contact lens design. Variables associated with the employee’s industrial arena include dust and airborne debris levels, presence of vapors or gases, exposures to chemicals and of course the prescription itself. Based on the information supplied by the employee, the doctor’s final choice of a contact lens may have a larger diameter to protect the eye from debris. Or the doctor’s final choice of contact lens may consist of a plastic material which is more resilient to dirt and debris collecting upon the contact lens surface. The doctor may determine contact lenses are not appropriate and advise against providing a prescription for contacts in an industrial environment.

My office recommends the employee bring to the doctor a summary of their visual information as it relates to how they use their eyes during their work activity. My office designed a document we call WIDE (short for what I do with my eyes) to facilitate this communication of the employee’s visual information. WIDE describes for the doctor what the employee’s on the job visual demands are and the work environment. Extremely critical to bifocal wearers; WIDE helps the doctor understand the unique distances not always found in a text book which are involved with the employees work activity. (You can find a copy of WIDE on our website at www.wecare4eyes.com/WIDE.htm.)

I personally recommend to every employee who wears contact lenses in an industrial setting that they keep at their place of employment 4 contact lens support materials.

Lubricants: All contacts become dry as they are worn on the eye. A combination of debris coating the contact lens and a reduction in blinking as we fatigue contribute to dryness. A contact lens lubricant maintains the proper moistness level and is essential to the contact lens performance during the work day. Long gone are the days when saliva could be used for lubrication. And drops designed for “getting the red” out of your eyes will usually permanently destroy that contact lens if used while the contacts are worn on the eye.. (For specific guidelines refer to our lubricant guide on our website at www.wecare4eyes.com/healthnews.htm.). Carrying case: when filled with fresh solution, provides the safest way to store a contact lens if lubrication does not improve the contact lens performance. A glass of water is not a safe or sterile alternative. In my experience most contact lens loss or damage can be traced to the fact that no case was available. Back up contact lens: Usually a contact lens is uncomfortable when debris has built up on the lens surface, a rip or tear has developed along the lens edge, or a crack has occurred in the body of the contact lens. A back up contact lens allows the employee to replace the uncomfortable lens with a fresh new one. If the eye is still uncomfortable or irritated the contact lens should be removed and the eye doctor consulted. And wear safety glasses! Safety glasses: What better way to continue your work day endeavors safely and comfortably! Back up safety glasses won’t help you if they are at home on the dresser. The safety glasses prescription should also be up to date. If the prescription is over 2 years old chances are you won’t see as well as you should to perform your best on the job. Bottom line; employees who wear contacts must understand the risks and the potential hazards of wearing contacts in an industrial environment. And wearing non prescription protective eyewear over the contact lenses is essential to guard against eye injuries.

Employers who permit employees to wear contact lenses in an industrial environment should consider these aspects. I strongly advocate a contact lens policy. Currently only one general application OSHA standard is in force to specifically address contact lenses worn in an industrial environment. This rule/standard (3) recommends against contact lens use when working with acrylonitrile, dibromo, chloropropane, ethylene oxide, ethylene chloride, and ethylene dianiline chemicals. Your office should review the work environments in accordance OSHA 29 CRF 1910.132 (d) to assess the requirements for protective eyewear.(4). My recommendations is 3 factors should determine if contact lenses are inappropriate for any given area in an industrial environment. Does this area already have a documented history of eye injuries and thus pose a potential hazard to the contact lens wearer? Please note: chemical splashes currently account for 20% of eye injuries and flying debris 70% of eye injuries. Does wearing contact lenses place the eye at greater risk of eye injury? Do contact lenses conflict with any existing safety requirement or strategy? Be sure to identify to both employees and visitors any areas where the use of contact lenses is prohibited and restricted. Include in your contact lens policy employee compliance with the 4 contact lens support materials as detailed earlier: lubricant, carrying case, back up contact, and safety glasses Another section should incorporate the utilization of WIDE to ensure the doctor has the employee information to design or deny a contact lens. I strongly suggest employees should have an identification on their personal IDs to clearly signal he or she is wearing contact lenses.

First responders and safety personnel should be trained in the detection and proper handling of contact lenses even if these responders and personnel have worn contacts. My experience with contact lens wearers is over time they tend to develop poor personal handling/maintenance techniques which could adversely influence their emergency techniques. Training should cover both rigid and softlens contacts as the techniques are different. If an employee is unable to remove the contact lenses; the eye can suffer an injury. And without proper training; an improperly removed contact by a first responder or safety personnel could also potentially injure the eye.

Your First aid center should include the following items to address contact lenses. Sterile gloves provide protection for first responders handling contact lenses. Tears in the eye can be a source of infection such as a simple case of conjunctivitis ( pink eye ) or as dangerous as the AIDs virus. Multipurpose solutions for both softlens and rigid contacts can be used to help loosen a contact lens if bonding to the eye’s epithelium has occurred. These solutions can also be used for temporary storage. Eye wash solutions are not appropriate for contact lenses due to the type of salt contained within them. Specially designed removal instruments referred to as “plungers” (DMV removal device) are helpful in the removal of a rigid contact lens from the eye. Glostrips are helpful in the detection of a contact lens if it has moved off center onto the eye‘s sclera (white part of eye). These strips are available for both rigid and soft lenses. Temporary storage contact lens cases prevents any loss or damage to the contact lenses once removed. A Data file should be maintained which lists both office and plant employees who wear contact lenses and the type: softens or rigid. My office offers a contact lens safety kit to our clients which includes many of these supplies. Your local optometrist can also be a source for obtaining these items for your first aid center.

Over the past 30 years in which I have worked with contact lens wearers; contact lenses have evolved from an expensive luxury to a very affordable commonplace visual accessory. Employers who permit contact lens usage should have a clear concise contact lens policy in force to guide their business operations and employees. First aid responders with proper training and resources should be capable of safely addressing contact lens issues in the event of an employee injury. And employees who wear contact lenses in an industrial environment must follow their doctor recommendations for safe, proper wearing and care. By implementing the protocols I have discussed; contact lens should not pose a greater risk to the employee themselves, first responders, or the business.

References

1. Vision Council of America’s 2006 consumer barometer www.visionsite.org

2. Food and Drug Administration website www.fda.gov

3. NIOSH Pub.2005-139Contact lens use in a chemical environment CIB 59

4. OSHA website www.osha.gov

Monovision Contact Lenses: Safe for your facility?

I

t’s common knowledge as we enter our 40s; our eyes begin to experience difficulty reading. If you’re a contact lens wearer; returning to wearing bifocal glasses sends cold shivers down your spine. And for decades many contact lens wearers have opted for Monovision contacts over glasses. Monovision describes a technique which has one eye wearing a contact lens for distance and the other eye’s contact lens is designed for reading. The eye doctor determines in the examination your dominant eye and this eye receives the distance prescription. Usually if your right handed; the right eye is the dominant of the two eyes. In most work instances Monovision contacts work at an acceptable level. But as the need for more reading power increases with our age, the disparity between the two eyes functioning becomes more pronounced.Please understand that all Monovision contacts do compromise the distance and near acuity. Our eyes are designed to see as a team or binocularly. Monovision contacts may not be suitable for work that demands sharp distance vision, night time driving, and detailed close work. For this reason I recommend you consider this issue as a segment of your overall safety policy. The FAA does not permit commercial pilots to use Monovision contacts after a crash in 1996 which was attributed to the fact the pilot wore this type of contact lens (1).

Employers who permit employees to wear contact lenses in an industrial environment should consider these aspects. Currently only one general application OSHA standard is in force to specifically address contact lenses worn in an industrial environment (2) . This rule/standard recommends against contact lens use when working with acrylonitrile, dibromo, chloropropane, ethylene oxide, ethylene chloride, and ethylene dianiline chemicals. Your office should review the work environments in accordance OSHA 29 CRF 1910.132 to assess the requirements for protective eyewear. My recommendations is 3 factors should determine if contact lenses are inappropriate for any given area in an industrial environment. Does this area already have a documented history of eye injuries and thus pose a potential hazard to the contact lens wearer? Please note: chemical splashes currently account for 20% of eye injuries and flying debris 70% of eye injuries. Does wearing contact lenses place the eye at greater risk of eye injury? Do contact lenses conflict with any existing safety requirement or strategy? Be sure to identify to both employees and visitors any areas where the use of contact lenses is prohibited and restricted.

Another technique to achieve a Monovision functionality is accomplished during corrective eye surgery. In this process one of the eyes is purposely under corrected to achieve the ability to read without using glasses. Highly popular among those in their 40s who want to completely eliminate the need for glasses. While the eyes can learn to work one for distance & one for close; I would recommend that individuals seriously consider if they are comfortable with this visual acuity

Visual performance in my opinion is too often overlooked as a critical component of a comprehensive safety program. With 43.3% of today’s workforce over age 44 (3) and in the next seven years the number of employees from age 55 - 64 to increase by 36% (4) , I believe Monovision contact lenses will become more prevalent in the workplace and an issue to consider in employee safety.

1. A Unique Contact Lens-Related Airline Aircraft Accident

www.hf.faa.gov/docs/508/docs/cami/00_18.pdf

2. NIOSH Pub.2005-139Contact lens use in a chemical environment CIB 59

3. US Bureau of labor website March 2009 statistics

4. Personal Touch by Theresa Y. Schulz June 2009 Occupational Health & Safety magazine